How to make a plastic pallet mould? The whole process of making plastic pallet mould is: three-dimensional design analysis of plastic pallets, plastic pallet mould design technical meetings, mould design testing, steel testing, quality monitoring during mould processing, dimensional testing after processing, and quality during mould assembly Monitoring, testing before mould testing, mould testing, mould repair, shipping. details as follows:

After receiving the customer's product design, we will immediately summon all relevant technical personnel to analyze their shortcomings and possible problems encountered in the processing process. For example, analysis of release angle, strength, plastic filling, deformation, wall thickness, skin texture, etc. After these discussions, the mould flow analysis is carried out immediately. If any problems occur, we will immediately contact the customer and provide solutions or suggestions

All relevant personnel will participate in the new mould design technical meeting. At the meeting, we will put forward all the technical points, such as: the use of mould parts steel, the basic structure of the mould, the plastic material and its melt index, the customer's special requirements, injection moulding machine parameters and parts processing steps, etc.

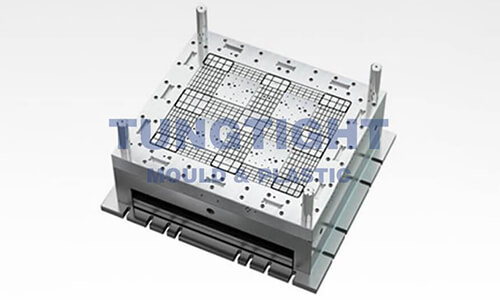

After the pallet mould is designed, the mould design review department will review the design. These audits include: "mould structure inspection", "mould motion and guidance system inspection", "mould injection system inspection", "mould cooling system inspection", "mould ejection system inspection", "mould vulnerable parts inspection"

After the design of the pallet mould was confirmed by the customer, we began to sample the steel material with high-quality testing equipment to ensure that there were no cracks or impurities. Moreover, the steel hardness tester can measure whether the hardness of the steel is qualified or consistent.

In the process of mould processing, we will also carry out basic quality control of steel. The processing is divided into three steps: the first step, rough machining; the second step, semi-finishing of some precision moulds; the third step is high-speed milling and finishing. We have always paid attention to the anti-deformation control of steel materials during processing.

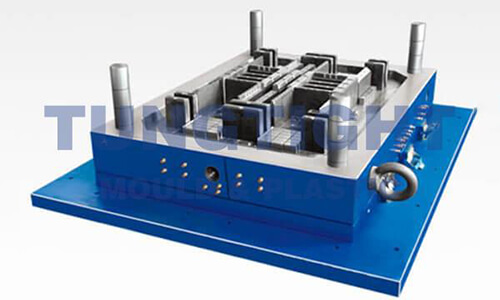

After the mould is processed, Tungtight has two coordinate measuring instruments and one projection measuring instrument to measure the cavity, core and other parts of the mould. The qualified ones will be sent to the assembly workshop, otherwise, the mould will be reprocessed.

Our quality inspectors and project managers will perform quality control on mould assembly. Before the first mould test, the mould will be disassembled for inspection by the quality inspection department according to the standard of the mould test. If it fails, the mould test is not allowed. After that, it is necessary to find out the deficiencies of the mould and provide solutions until it can be shipped out.