Because the low cost, high output, the ultra-thin products is more and more popular with the businesses. Thin wall products are widely used in food packaging and medical treatment. When we go to a restaurant and want to take our food away, the waiter will use a box to package the food. It is clean and easy to pack. When we go to the supermarket, we can find many food and snacks packed in thin wall container.

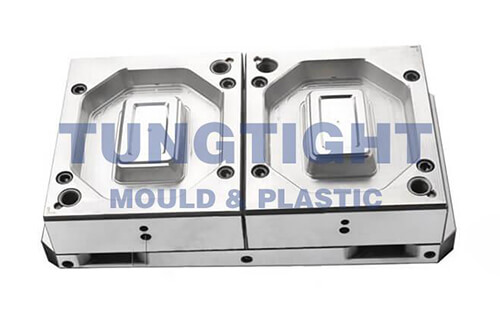

With more than 15 years of experience in the production of thin wall moulds, has extensive experience, Tungtight mould can provide customers with a complete thin wall mould solution. Tungtight mould attaches great importance to thin wall injection molding technology, with the market demand for Food container mould specification diversification, productivity is always the same requirements, Tungtight mould is also from 1 to1 cavity, 1 to 4 cavity and 1 to 6 cavity of disposable food container mould, mold performance improvement is a real benefit for customers. Thin-wall products need equipment including plastic thin-wall mould, plastic high-speed injection machine, robot, auxiliary machinery such as chiller.

Tungtight mould professional development, design, production, and sales of high quality thin wall mold. The production of thin-walled products requires changes in the conventional processing process, higher injection pressure and injection speed, shorter cooling time, and higher mould temperature.

Some tips for making Food container mould:

At present, the popular shapes are round, square and oval in the market and the routine capacities are 500ml, 750ml and 1000ml. According to the shape, specification and gram weight of the product, different mold sizes, cavity number and wall thickness need to be designed. At present, the minimum wall thickness of the lunch box designed by our company is 0.35mm, and the wall thickness can be uniform.

The wall thickness of the box mold is very thin, in the high-speed injection, the mold needs to bear very high pressure, so the thin-wall mold needs high hardness steel. Therefore, Tungtight mould are using S136 or H13 steel material, the hardness can reach HRC 42-45 degrees after quenching. To prevent the mold deformation under long-term high speed and high pressure causes flashing of product, increase the cost and other problems.

Tungtight mould has a professional design team to optimize the mold, thin wall mould design needs to consider the following points: product parting surface, product wall thickness design, exhaust design, water channel design, blowing position and direction design, these problems directly decide the quality of a thin wall mould.